A Comprehensive Hygrothermal Analysis of the Ezy Fit Green IWI System

Ezy Fit commissioned Ecosophy Studio to carry out a comprehensive hygrothermal analysis of their new hemp-based Green Internal Wall Insulation (IWI) system to understand its moisture behaviour and feasibility across different climatic conditions and existing wall types. This technical assessment supported continuous product optimisation and contributed to the system successfully achieving KIWA certification.

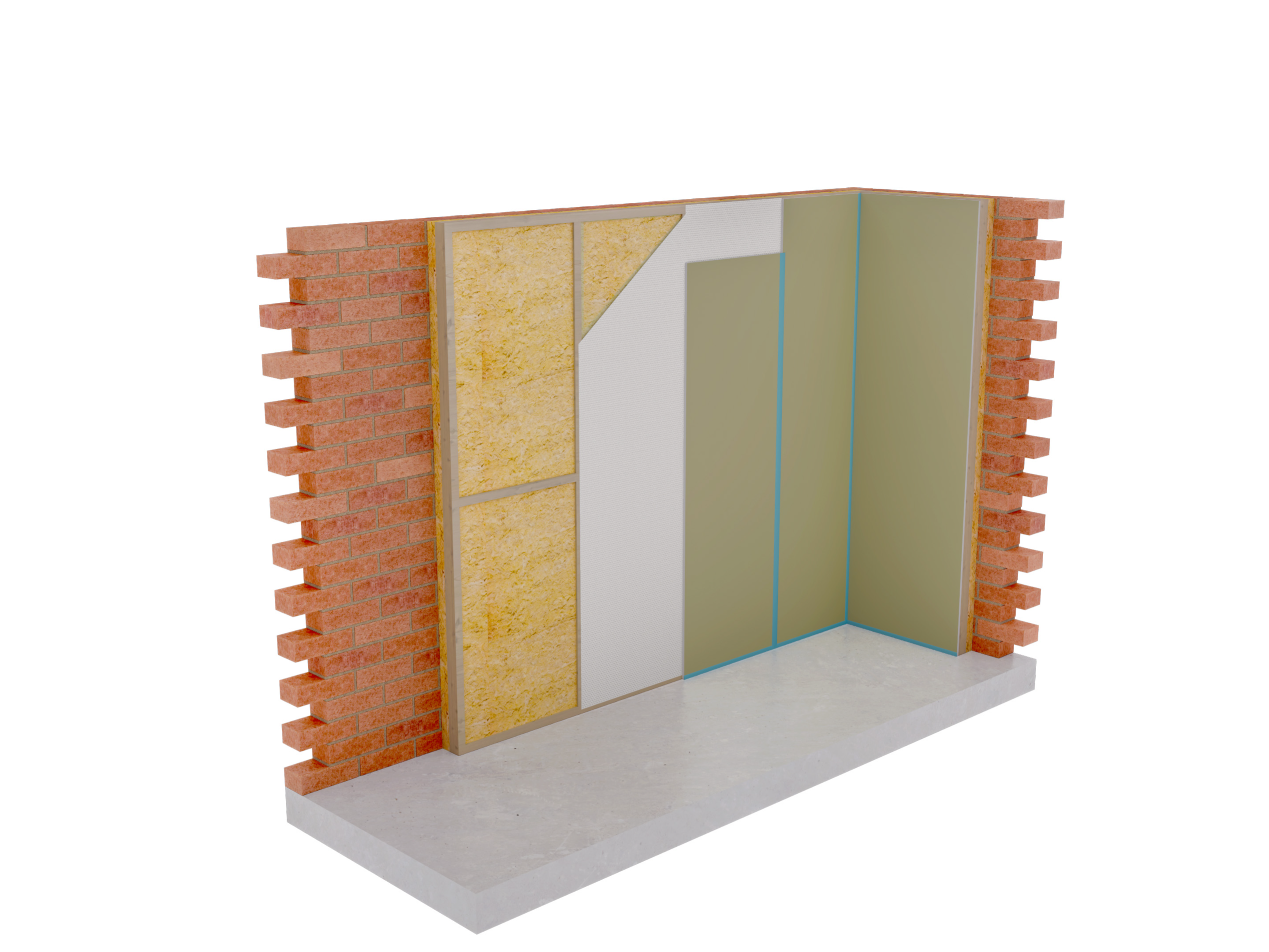

The Ezy Fit Green IWI system consists of IndiTherm® hemp insulation batts fitted between timber studs and IndiBreathe® Flex hemp–jute insulation rolls stapled to the back of the timber frame as a stud-backer layer. The timber stud frame is mechanically fixed to the existing supporting wall.

The support provided by Ecosophy Studio comprised three complementary types of analysis:

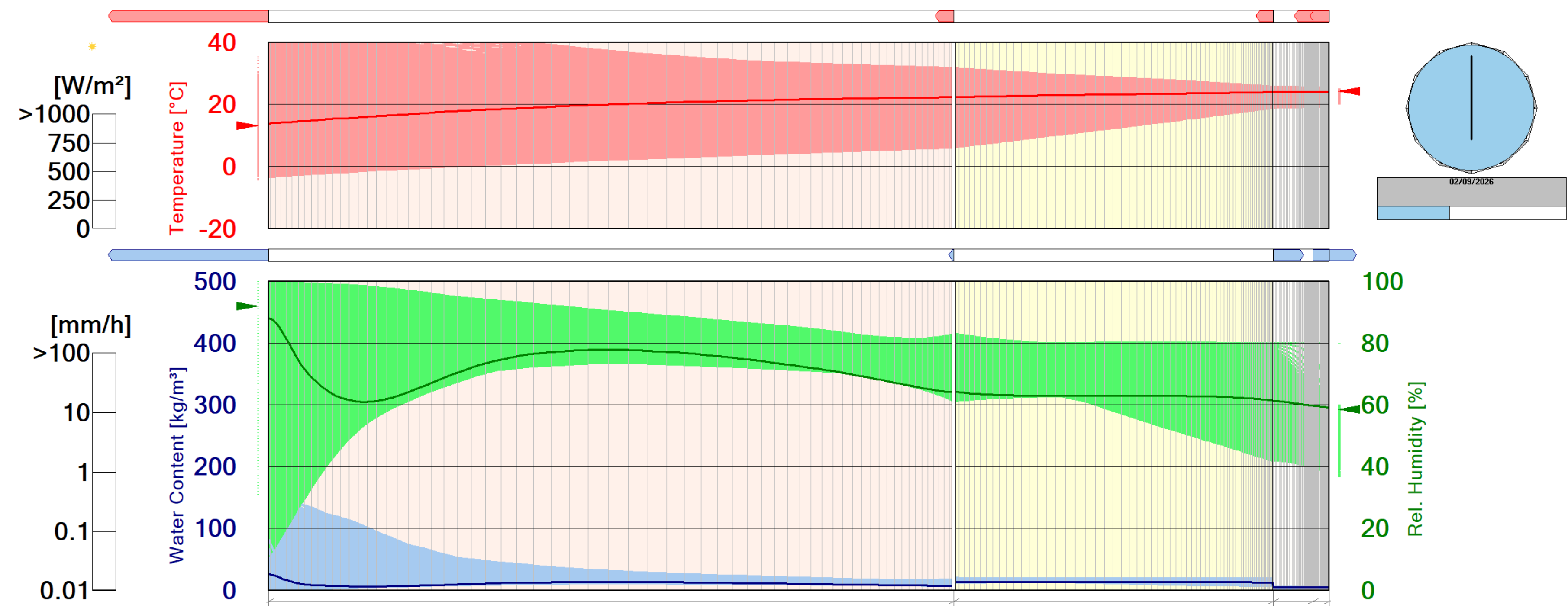

1. Dynamic hygrothermal modelling

Using the WUFI® software family, we assessed the system’s moisture behaviour under a wide range of external UK climates, indoor conditions, and existing wall substrates including several brick and stone types with varied hygrothermal properties. This allowed Ezy Fit to identify the conditions under which the Green IWI system can be safely installed, ensuring protection against moisture-related risks such as interstitial condensation and mould growth. The analysis also informed targeted design improvements by clarifying the influence of individual system components on overall hygrothermal performance.

2. 2D thermal analysis of junctions and connective effects

Connective effects are among the most common causes of elevated moisture risk and defects in insulation systems. To address this, we conducted a series of 2D thermal analyses examining heat flow at key construction details, including corners, ground-floor junctions, intermediate floor connections, and window/door openings. These insights informed optimisation of the system at junctions, reducing thermal bridging and lowering associated moisture and performance risks.

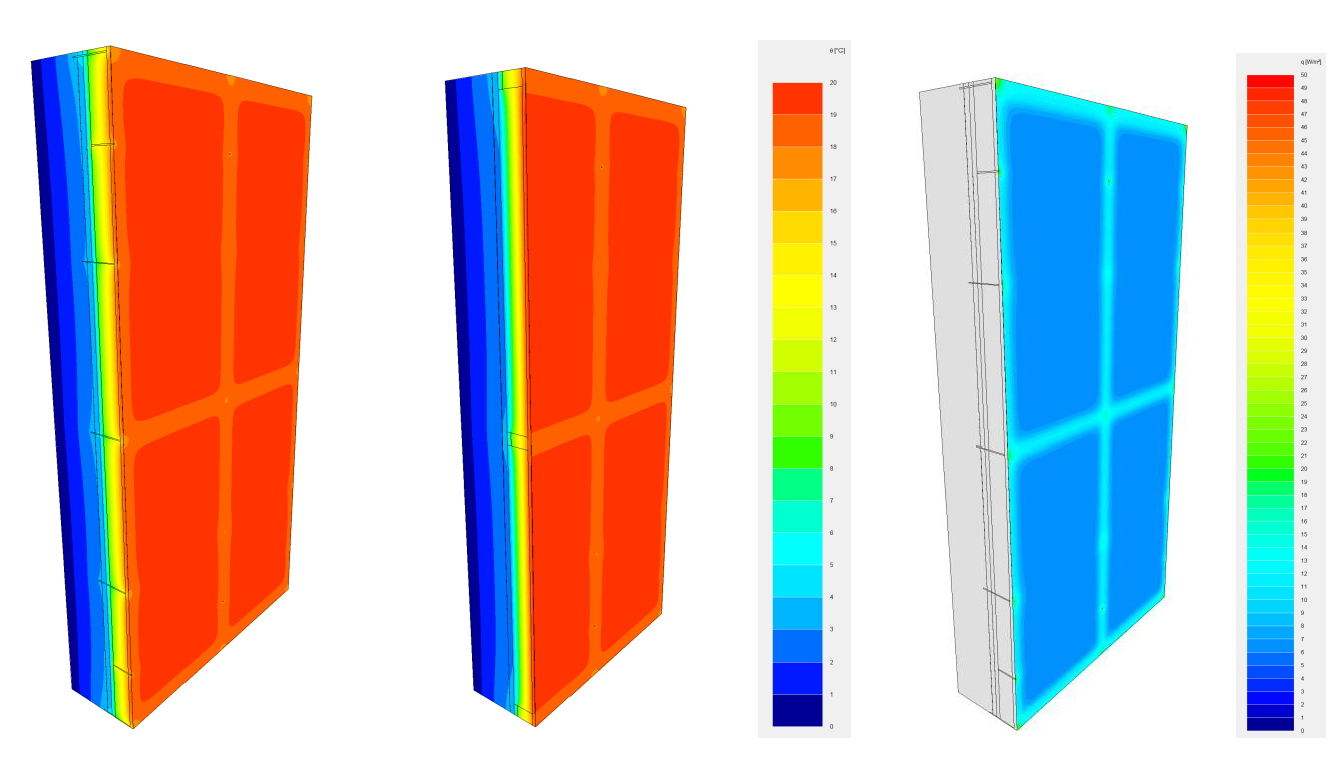

3. 3D modelling of mechanical fixings

Finally, we assessed the influence of mechanical fixings on the hygrothermal and thermal performance of the system. Achieving the right balance between structural stability and thermal efficiency is critical: poorly specified fixings can significantly increase thermal bridging and create localised condensation risks. Using high-precision 3D thermal modelling, we optimised fixing selection and arrangement to minimise moisture risk and achieve the highest possible thermal performance. This analysis also enabled realistic and precise U-value calculations, giving Ezy Fit and their clients an accurate understanding of the system’s overall thermal performance.

Together, these analyses provided Ezy Fit with a robust foundation for product development, supporting a sustainable, moisture-safe, high-performance internal wall insulation system ready for real-world application.